Here’s a recent stairlift repair we carried out in Leeds, West Yorkshire. In this one, the stairlift had a folding rail which was colliding with the floor and causing a problem. The mechanism wasn’t closing properly because of this issue and the chair was scratching the join each time it passed over it.

After identifying the problem we moved the rail upwards on the sliders. This required loosening of the bolts and forcing the rail upwards slightly to create more room.

Stairlift Repair Near Me – Case Study in Leeds

Folding mechanisms are generally reliable but can cause problems. A recent removal we did in Leeds had an issue with it’s power, so had stopped working properly.

We like the Flow X stairlift when it comes to tackling a doorway at the bottom of the stairs. The Flow X has a drop nose rail which can sit very close to a downstairs door. Fewer moving parts generally means there’s less potential for problems in the future. Here’s a picture of the drop nose rail on a Flow 2a stairlift.

Stairlift Repair Near Me

With the rail moved upwards, this gave more clearance space for the rail to close properly and solved the problem. The tricky part of this repair was the weight of the rail + stairlift. Luckily I was on hand to help Scott with this repair which needed two of us – one to hold the stairlift up, while the other physically lifted the rail and slid it upwards on its legs. Once this was done the problem was solved!

Not content with just a repair, Scott, (ever the perfectionist) noticed another problem! When testing out the repair he noticed there was very little leg room at the base of the stairs and the client was a similar size to Scott, so would have the same issue.

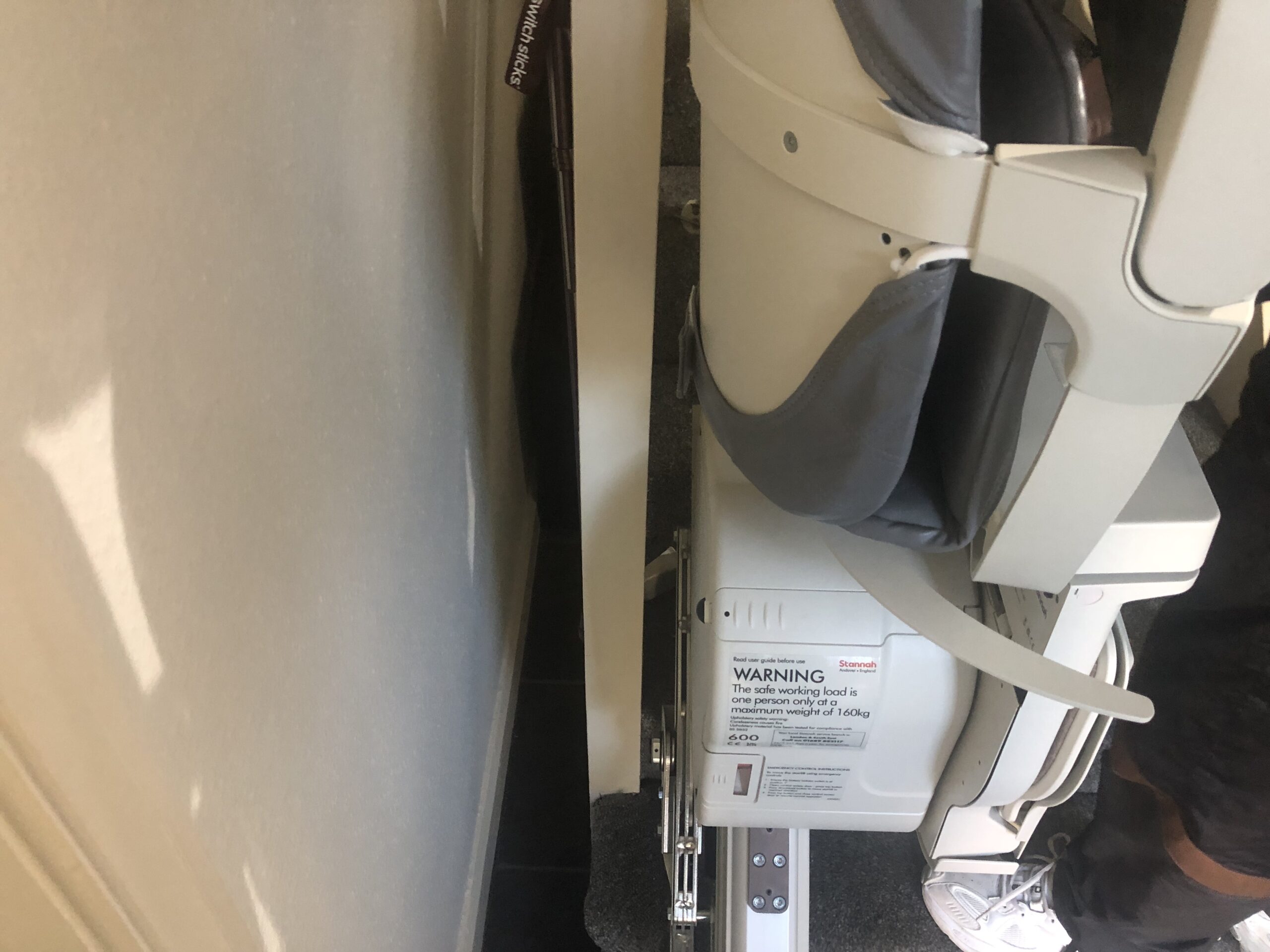

The rail was quite far from the wall and so there was some room for manoeuvre here. The Stannah 600 is particularly good here because it can be set quite far back against the wall. Stannah have done their homework with regards to this, and this is exactly the reason we often choose their stairlifts for narrow stairs.

As you can see in the pictures, this staircase was pretty narrow! Scott was able to move the stairlift rail back towards the wall a touch which allowed slightly more leg room!

Summary

This stairlift repair in Leeds was relatively straight forward and required the rail to be moved upwards. This was a two man job however because once the stairlift rail is loosened from the legs, the whole rail would have fallen downstairs with the weight of the chair and the rail! Scott needed a hand to hold the stairlift upwards and take its weight while he pushed the rail upwards and tightened the screws simultaneously!

Once the rail had been moved, there was more room for the moving rail to sit comfortably without hitting the floor. This meant that the mechanism could close properly without clashing with the chair mechanism as it passed over the join.

With the main job done, more leg room was also created by moving the rail slightly back against the wall.

That’s the way we roll here at UKStairlifts.com!

Got a repair or in need of a stairlift? Give us a call on 0800 046 3438.

You can checkout the video of this repair below: